Latest news

Read the latest news from the Centre for Sustainable Materials Research and Technology

Image caption: Veena and Andrew at Kandui's Nowra facility containing SMaRT's Green Ceramics MICROfactorieTM Technology.

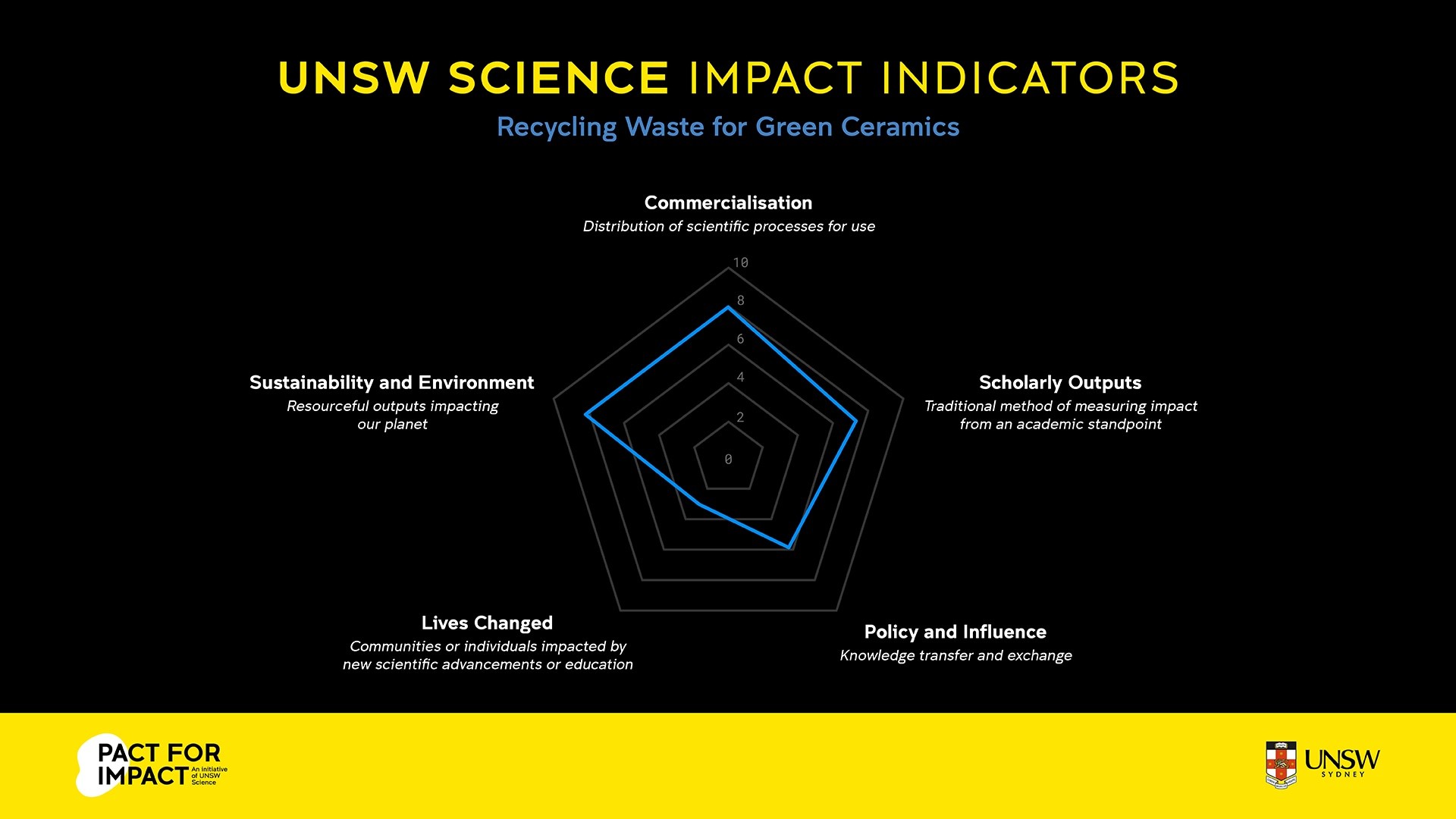

The unique collaboration between UNSW SMaRT Centre and industry partner Kandui Technologies has advanced SMaRT's Green Ceramics MICROfactorieTM Technology into a commercial reality.

As explained in this UNSW Science story, the collaboration spans a decade and lots of hard work to successfully reform waste textiles and glass into silicone dust-free ceramic tiles used in kitchens, bathrooms and in many built environment applications across the world.

The world and our environment is in a state of flux, and as the pressing reality of the climate crisis comes into sharp focus, we need answers.

One of the key challenges in the pursuit of a sustainable future is tackling the vast amount of waste generated by humans. And for big problems we need big solutions, and a unique partnership is taking this particular challenge head on.

“Some people may look at rubbish and see a pile of waste, but you have to look at the value within,” says Scientia Professor Veena Sahajwalla, Director of the UNSW Centre for Sustainable Materials Research and Technology (SMaRT Centre).

Prof. Sahajwalla, a leading expert in recycling science, has been working in partnership with Mr Andrew Douglas, the founder and Director of Kandui Technologies, to transform waste materials into highly-engineered, valuable products.

“Applying the science that has been developed at the UNSW SMaRT Centre, we are turning low-value materials like waste glass and textiles into high-performing and high-value products such as ceramic tiles and benchtops,” says Mr Douglas. “This is all done on a small but commercial scale at our factory on a landfill site in Nowra.”

"It’s incredible to see how this unique partnership with Andrew, which is built on respect and communication, has resulted in real solutions, with real impact” says Prof Sahajwalla. “We have taken mutual ownership of the problem to look for answers, whilst always valuing the science.”

Amongst the tonnes of household waste sent to landfill every year are valuable materials that have the potential to be transformed into brand-new products.

Together with her team at the SMaRT Centre, Prof. Sahajwalla developed a process that takes waste resources not traditionally used for recycling, which are often made up of complex materials, and transforms them into high-value products. She coined the process ‘micro-recycling’.

After years of development, the world’s first MICROfactorieTM was launched in 2018 harnessing micro-recycling to revive waste materials onsite, at the UNSW SMaRT Centre.

That very first MICROfactorieTM was just 50 square metres, and the perfect prototype for how other MICROfactoriesTM could be embedded into the community.

"Ultimately, a MICROfactorieTM is all about decentralisation,” says Prof. Sahajwalla. “The idea is that a small unit that couples both recycling and remanufacturing can enable communities to deal with their waste.”

Once it was clear that the process worked in the lab, Mr Douglas was the first to set up a MICROfactorieTM embedded in the ‘real world’, firstly in the small town of Cootamundra, and more recently in Nowra, a city in the South Coast region of New South Wales.

The MICROfactorieTM based on the landfill site in Nowra is using the micro-recycling process to turn waste glass and textiles into stylish and sustainable ceramics that can be used for kitchen benchtops, table tops and tiles.

“We're pioneering micro-recycling here at UNSW. And our partnership with Andrew is now taking waste mattresses and creating Green Ceramics – ceramic tiles made from 80 per cent recycled materials – on a small but commercial scale.”

- Professor Sahajwalla

Prof. Sahajwalla and Mr Douglas have known each other for over a decade, having first met in passing at a sustainability conference. Their successful partnership has been one of learning and collaboration.

“Mine and Andrew’s values are aligned,” says Prof. Sahajwalla. “We care about the impact of the work we do and we all aspire to deliver to a world that’s not a perfect place.

“Thinking about how we can improve outcomes for our people and our planet is at the core of what we do.”

From the periphery, Prof. Sahajwalla and Mr Douglas’ day-to-day jobs may seem quite different.

“It might look as though we work in our own spheres – like Andrew is coming from the world of business, and I am tackling the science” says Prof. Sahajwalla. “But that’s not the case for us, the science and the manufacturing are intertwined, and the partnership itself has helped to shape the fundamental research we are continuing to do.”

But what motivates these two experts to tackle some of the most pressing problems facing society today?

The answer: a passion for change.

“I saw an opportunity to change and disrupt the traditional approach to a problem,” says Mr Douglas. “Luckily, I bumped into Veena who blew it all out of the water. She said ‘open your eyes and have a look at what's out there’ and that ripped the band aid off for me, I was in on the journey.”

Mr Douglas emphasises that no journey is linear and, like any success story, there are challenges along the way.

In fact, the very fundamentals of micro-recycling pose some serious hurdles. “Everything that contains more than a single type of material, such as a mattress, gets increasingly difficult to recycle,” says Prof. Sahajwalla. “This means the commercialisation of the products we’re creating, has only been made possible once the fundamental science of micro-recycling has been understood.”

With issues that do arise, it’s important that the wider team is able to communicate to provide the best platform for learning and growing, the pair emphasise.

This story is not simply one of financial investment, but also of human investment; both have committed endless time and boundless energy to make their vision a reality.

The benefits of such an open, communicative partnership means that Prof. Sahajwalla and Mr Douglas are able to refine both the process and the products. “It’s at the point where we've got our staff members embedded at the Uni, and the Uni representatives are always down at the factory. It's just seamless, and importantly, the relationship allows us to share our learnings from the factory floor,” says Mr Douglas.

“It’s really healthy because we are always challenging each other. And the beauty of that is that if we will hit a production problem or a specification problem, we can feedback that we need to tweak something. And that’s what makes this collaboration so effective.

““Any challenges we face, we approach with fun. No matter how difficult it’s been, there's always a chuckle and a reset at the end of the day. So that's what makes it so enjoyable."

- Mr Douglas

Even just ten years ago, the world of recycling and sustainability was a very different landscape, and Prof. Sahajwalla and Mr Douglas have seen it evolve. And now, both stand at the forefront of an industry that is continuing to push boundaries.

“We've made the point that these methods are good for the environment and good for recycling. But now we’re notching up another level, one that has never been talked about in green manufacturing before, which is ‘how is it better from an operational and production point of view?’” asks Prof. Sahajwalla. “It was always assumed that if you're putting waste into manufacturing, then you must be spending more to create lower grade products, and that’s simply not the case.”

As well as contributing to a circular economy, micro-recycling actually reduces the energy requirements of 'traditional’ manufacturing by overcoming the energy-intensive extraction and processing required of natural resources.

“We’ve actually shifted the dialogue to highlight the operational benefits of micro-recycling. And the world now seems to be excited about the possibilities.”

- Professor Sahajwalla

Prof. Sahajwalla emphasises the need to think about the bigger picture.

“The world is never going to run out of waste. So, if we can keep these materials in our supply chains in a safe and a sustainable manner, then the opportunities are endless.”

The commercialisation of Green Ceramics is just the latest development in their ongoing collaboration.

Mr Douglas says the interest in their work is growing daily. “We're getting inundated with every type of textile known to man, being contacted by every garment manufacturer, every retailer, government agencies, hospital waste. We're growing and one day we want to have capacity to be able to accept all of it.”

When they reflect on the journey so far, both Prof. Sahajwalla and Mr Douglas are excited about the possibilities and proud of what they have achieved.

“At the end of the day, it's cutting-edge science with environmental impact, it's safe products and it's creating local jobs. What's not to love?” says Mr Douglas.

“I am hopeful that the work we do in our partnership inspires others to consider how they can be a part of the story,”

-Prof. Sahajwalla.

The crystalline silica-free ceramics are available from the trading branch of Kandui, Noveco Surfaces.